In the world of Labeling and Coding, there is a myriad of ways to accomplish your goal. Labels can be applied as a merge, blow-on, corner wrap, tamp-blow, or full wrap around. Date and Lot coding can be accomplished using a direct thermal transfer, Piezoeletric ink jet, continuous ink jet, laser coders, UV LED curing systems and more. Packaging Systems carries a range of products that can be custom fit to your specific application. Whether you are looking for speed, low volume, or 24/7 operation, we can help you find the right Labeler or Coder for your project.

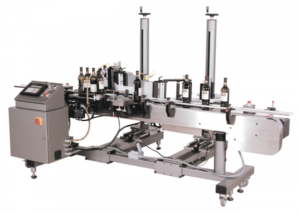

Label Applicators

-

- Packaging Systems offers the most trusted name in the labeling industry, CTM Labeling Systems.

- Color touchscreen with easy-to-use machine operator interface.

- Stepper motors with micro pulse driver allows superior accuracy that can dispense labels up to 3000 inches/minute.

- Merge, blow-on, tamp-blow, corner wrap, or full wrap around label application.

- Custom label applicators for a new line, or full integration with an existing line.

- Contact a sales associate today to see how we can help your next labeling application.

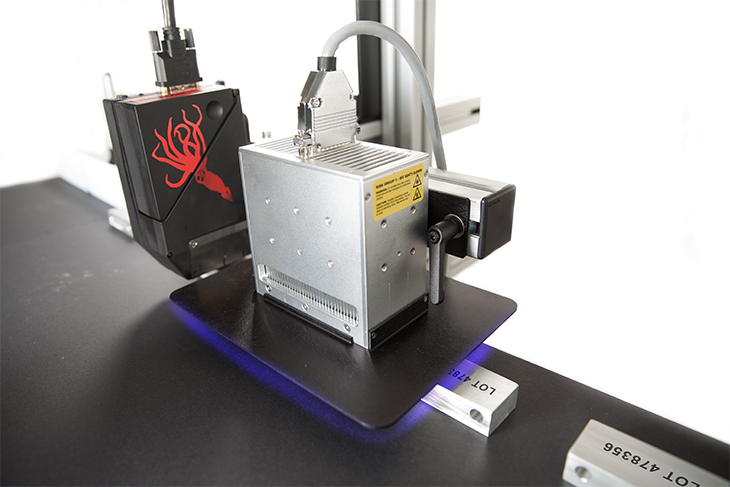

Date and Lot Coding Systems

-

- Packaging Systems offers a robust line of date and lot coding systems.

- High Resolution Ink Jet

- Continuous Ink Jet

- Thermal Transfer Printing

- Laser Coders

- DOD Large Character Printers

- UV LED Ink Jet Curing

- Wide application range from low volume ink jet to high speed laser coding and more.

- Contact a sales associate today to see how we can help your next date and lot coding application.

- Packaging Systems offers a robust line of date and lot coding systems.