Whether looking for automatic high performance strapping machines for full pallet loads, or looking to bundle small products together with plastic strapping, Packaging Systems, Inc. has the solution for your application. When your pallet load needs additional support, beyond stretch film, strapping the load to the pallet using polyester or polypropylene strapping can provide the extra stability needed to securely deliver products to your end user. Some common applications includes distribution of brick and block, paperboard, plastic bottle manufacturing, domestic appliances, and timber.

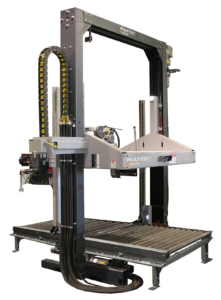

Automatic Pallet Strapping Systems

-

- Packaging Systems carries high performance side seal and top seal strapping machines.

- Designed to be low maintenance and operator friendly for a high level of dependability.

- Capable of standard undertrack style strapping or an optional pallet bayonet for through pallet strapping.

- Compression system and sealless joint technology offer the performance needed to protect your product in transit.

- Contact a sales associate today to see how we can help your next strapping application.

Table Top and Hand Held Strapping Machines

-

- Packaging Systems offers a robust line of table top strapping machines for nearly every industry.

- Battery Powered Hand Held, Semi- Automatic, and Automatic machines for every level of production.

- Custom arch sizes for unusual product sizes. Optional photo eyes for full automation.

- Machines can run polyester strapping, others capable of polypropylene strapping.

- Contact a sales associate today to see how we can help your next strapping application.

Efficient Packaging with Automated Strapping Equipment

In today’s fast-paced world of manufacturing and distribution, efficiency is critical. One area where automation has made a significant impact is in packaging and strapping operations. Automated strapping equipment, including automatic pallet strapping systems, has revolutionized how goods are bundled and secured for shipment.

At its core, strapping equipment utilizes high-strength plastic or steel strapping to bundle products together tightly. This ensures loads remain intact during handling and transportation. Manually strapping pallets and bundles is labor-intensive, time-consuming, and prone to inconsistencies. Automated systems eliminate these pain points.

Automatic Pallet Strapping Systems

Pallet strapping systems automate the process of securing goods stacked and positioned on a pallet. These systems typically integrate with conveyor lines, precisely detecting when a full pallet load has been accumulated. Once detected, the strapping head extends around the pallet to encircle the goods with strapping.

The strap is tightly tensioned to compress the load, improving stability and unitization. Sealing heads then join the strap ends together to create a secure loop around the pallet payload. Consistent strap tensioning ensures stable, shipment-ready pallets without the variability of manual strapping.

Many automatic pallet strapping systems also incorporate auxiliary operations. Pallet unitizers can be integrated to automatically slip a cap or top frame onto the strapped pallet for added load stability. Systems may also apply edge protectors, corner boards, or wrapping before or after strapping.

Other Automated Strapping Configurations

While pallet strapping is common, automated equipment handles bundles and packaged goods in other configurations too. Case strapping systems secure boxes or bundles traveling on conveyors with strapping. Bundle formers collect and square loose products into tight bundles before strapping them.

Strapping heads come in different styles for varying bundle sizes, weights, and production volumes. Systems can be fully or semi-automatic. Fully automatic systems integrate multiple strapping heads and conveyors for high-speed strapping of bundles from multiple lines.

Benefits of Automating Strapping

Versus manual operations, automated strapping equipment provides numerous benefits:

– Improve throughput and productivity with faster strapping cycles

– Enhance load security and stability with properly tensioned strapping

– Reduce shipping damage with stable, unitized loads

– Optimize strap usage and reduce material costs

– Boost worker safety by eliminating strenuous manual strapping

– Gain data tracking of strapping events and efficiency metrics

With the right system integrated into packaging lines, manufacturers can reduce costs while speeding operations and delivering a consistently secured product to customers and distributors.

Automated strapping tightens up the modern packaging operation. As e-commerce and supply chains grow increasingly complex, strapping automation will continue playing a vital role in efficiently bundling and shipping goods worldwide.