Stretch wrapping is often the last process in any production cycle before product is shipped to the customer. Just as any manufacturer prides themselves in the quality of their product, we pride ourselves in providing you the very best stretch wrapping equipment in performance, durability, and cost effectiveness. This is why Packaging Systems is partnered with Lantech®, a world leader in stretch wrapping technology and the inventor of the first rotary stretch wrapping machine. We offer equipment from entry level, low volume, semi-automatic turntable stretch wrappers, to high volume, fully automatic stretch wrappers capable of 180 loads per hour. In addition, Packaging Systems will keep you running longer by providing you the start-up, training, and support through our certified Lantech® technicians. For more help in finding a stretch wrapper, contact one of our equipment specialists today!

Semi-Automatic

-

- Packaging Systems offers the most trusted name in the stretch wrapping industry, Lantech®

- Turntable or straddle machine configurations

- Load Guardian™ option offers unique profiles for every load type

- Scale packages for accurate pallet weights, helps avoid LTL fines

- Pallet Grip® reduces damage by locking your load to the skid

- Auto Film Cut-off™ allows your operators to stay on the forklift

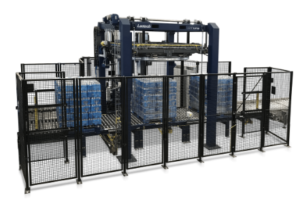

Automatic

-

- Packaging Systems offers the most trusted name in the stretch wrapping industry, Lantech®

- Turntable, Straddle, Ring Straddle, and Lan-Ringer model configurations

- Metered Film Delivery® system wraps with 2x the force without crushing or twisting the load

- Pallet Grip® keeps your loads secured to the pallet

- From 45 loads per hour capabilities up to 180 loads per hour

- Performance monitoring system provides instant wrap data feedback